Plastic wood material has good weather resistance and can adapt to various climatic conditions.

Whether it is under the hot sun or in a humid and rainy environment, it can maintain a better performance.

Qualified FRP material is a non-toxic and harmless material to human body.

With high strength and toughness, it can withstand a certain degree of impact without being easily damaged

Wood is a natural material that generally does not contain chemicals that are harmful to children's health.

In contrast to some synthetic materials, it does not emit harmful gases such as formaldehyde

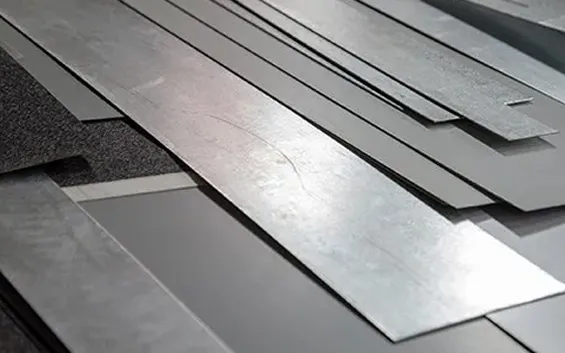

Due to the strength and rigidity of galvanized sheet metal, it can be used to build a variety of complex structures.

In the design of children's equipment, stable frames and connecting parts can be produced.